How WE BEND

We do it in quite a cool way. The bending and curling of tubes, shaped tubes, solid materials, special mouldings etc is part of the cold forming process. As the name suggests, the material is cold formed or made into the desired shape. At this stage, it is important for us to point out a few things and to provide you with a short explanation.

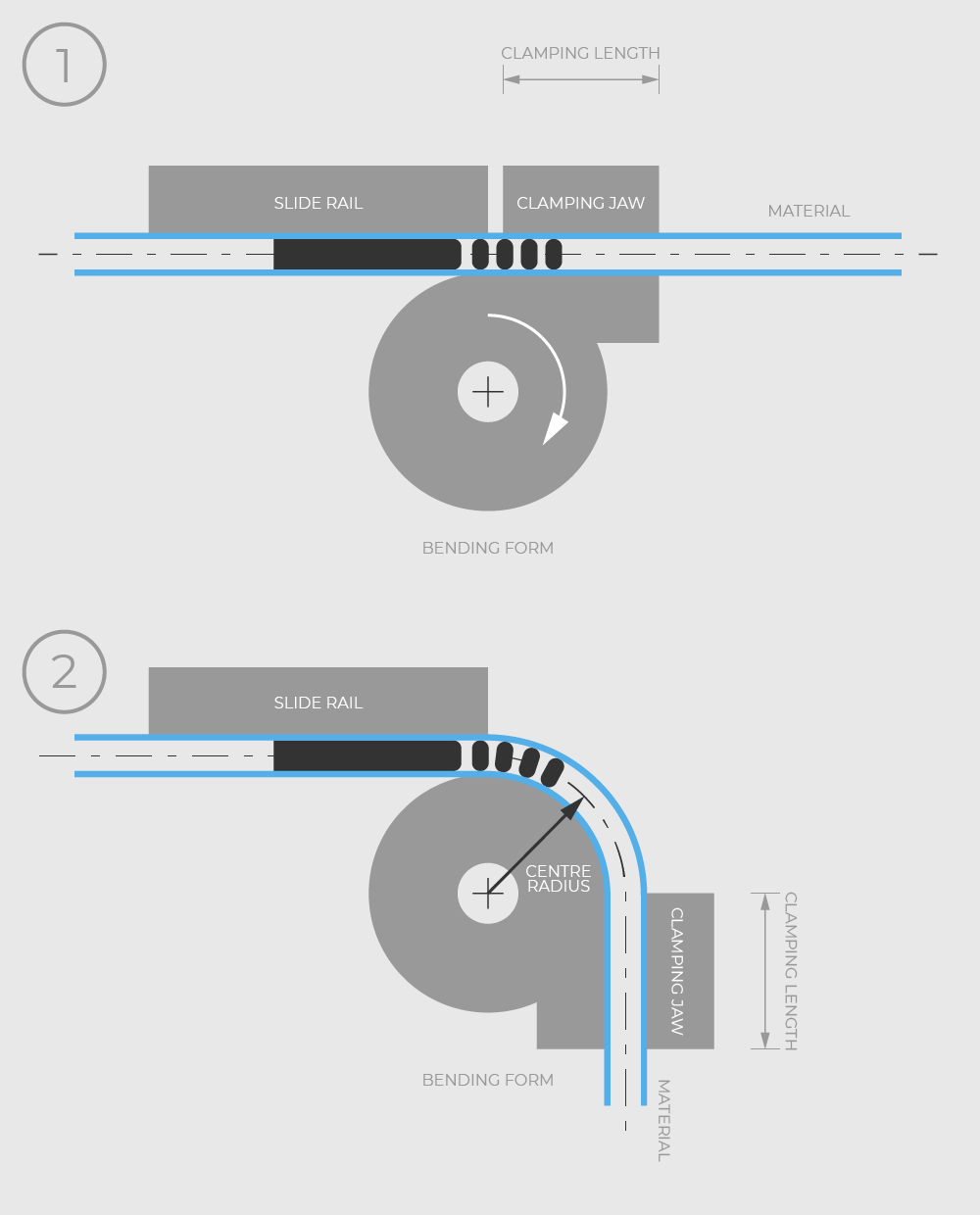

Mandrel bending

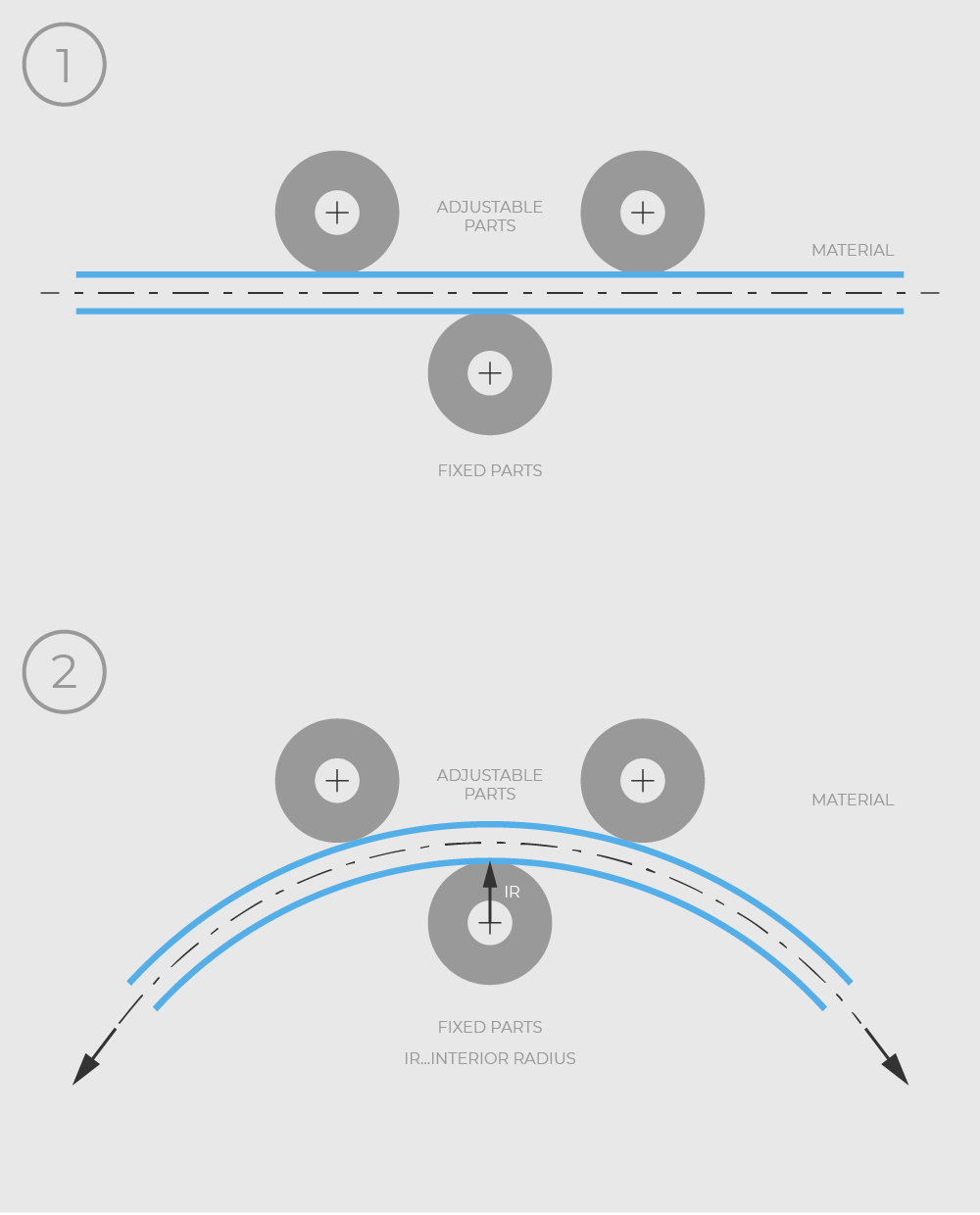

Curling

A creasing formation arises, if unsuitable material is used or bending radii that are too small are selected. That’s why it is particularly important to always clarify the feasibility of a concept with the customer in advance, in order to avoid any unpleasant surprises.

You should be aware that a cold formation may lead to visible effects, and that, with our longstanding experience and our own measures, we can counteract such a deformation.

Usually it is sufficient to use the next largest wall thickness, although, often, we have to fill and condense the materials with quarzt sand.

This requires a great effort on our part that we only offer for an additional charge, but which also enables a far greater spectrum of radii and materials.

However you decide – we will fulfil your wishes. Because we bend everything!